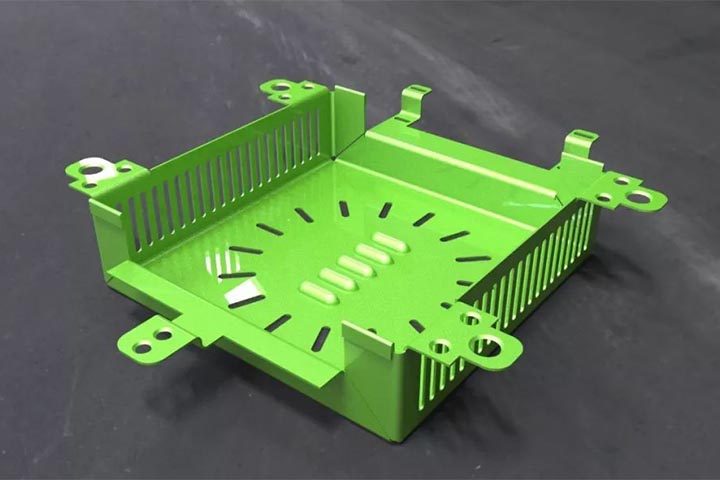

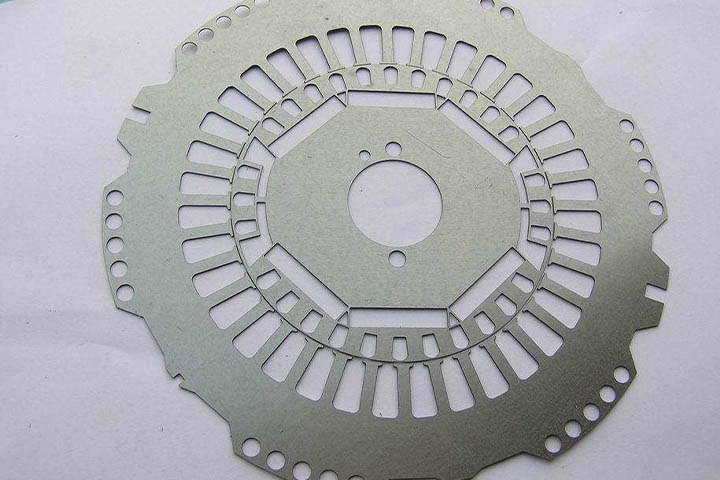

To have a better understanding of the precision sheet metal fabrication process, first, you need to know the basics. Precision sheet metal fabrication is a manufacturing process used to create highly accurate and detailed metal parts.

Examples of industries utilizing such parts include robotics, architecture, and aerospace. What techniques are they employed in precision sheet metal fabrication? We have quite a number; they include:

- Stamping: it’s a forming process that creates desired shapes through permanent deformation.

- Punching: involves the use of heavy machinery to put indents or holes into pieces of sheet metal

- Laser-cutting sheet metal is cut into custom shapes and designs using a high-powered laser.

- Shearing- In most cases, this process is used to cut smaller sheet metal sizes for further rapid prototyping.

View More

Since the techniques used in sheet metal fabrication are mostly done using automated machinery, it has made it possible to manufacture high-precision parts. These components are highly used in aviation, automotive, healthcare, and so much more.

Furthermore, the products are made from durable materials. A good example is steel. This results in good-quality parts that last longer.

We offer Reliable Precision Sheet Metal Fabrication Service:

A smooth sheet metal fabrication process requires good machinery and other tools. We at RM Mold have all it takes to provide the best in sheet metal fabrication. When it comes to precision sheet metal fabrication, RM Mold has all the necessary expertise, experience, and equipment to provide our customers with the finest services. You can trust RM metal fabrication service as our team of skilled engineers and technicians are well-versed in the latest fabrication techniques, ensuring that every product they create is of the highest quality possible.

Why You Should Choose Us for Precision Sheet Metal Fabrication?

A custom metal fabrication manufacturer can provide much in satisfying customer needs and necessities. Our precision sheet metal fabrication company offers the faith and proficiency to affect your bottom line. Even with a restricted budget, you don’t have to lose quality in search of cost-effective solutions. A skilled custom metal fabrication business can realize cost savings for its customers. From amplified efficiency to choosing the apt materials, here are five valuable ways to save money on custom metal fabrication project:

All-In-One Efficiency:

Custom metal fabrication projects comprise several comprehensive, intricate processes and phases from notion to completion. Precision sheet metal fabrication provides a one-stop-shop solution from prototype to manufacturing to assembly and packing and can reduce the added expenditures processes. Efficiency streamlines scheduling and production expands operations, and avoids costly errors and delays.

Quality Fabrication Method:

RM fabrication processes have several practices to produce quality components and parts for end products or further assembly. The raw material needs to be cut, designed, and precision metal molded into final products using a combination of fabrication techniques—common types of fabrication range from shearing, stamping, bending, and laser cutting. The number of fabrication methods used in a manufacturing process will hinge on the material, design, and desired end product.

Design Optimization:

Design optimization is an association between the customer and the fabricator intended to produce the highest quality product at the expected cost. Working with a skilled RM fabrication can offer valuable insight, concepts, and recommendations on everything facet of precision metal molded design, from selecting the best material to meet requirements to the fabrication techniques required for production. Design perfection is a creative endeavor that provides a more efficient and cost-effective process.

Selecting the Right Material

Whether you are using stainless steel, aluminum, copper, or brass, for sheet metal mold, the correct material has the power-driven properties required to meet the necessities of your product. Material costs are commonly the more significant part of any project. To save on costs, rm sheet metal advice, consider a suitable material with the properties required for the application to perform as planned. E.g., aluminum and stainless steel have corrosion-resistant aspects, but your material costs for one over the other can vary depending on volume and weight. On paper, aluminum is more expensive than stainless steel based on weight. By volume, aluminum is more inexpensive because you get more products due to its lightweight. Picking a suitable material with the required thickness can be cost-effective. When laser cutting sheet metal mold, thinner materials are cut at different rates, which can reduce the total price of laser cutting.

Value-Added Services:

We provide extra services besides manufacturing and precision sheet metal fabrication to help our clients meet their needs more effectively are value-added. To accomplish a fabrication project, one needs to safely transport high-quality rm sheet metal products. We can administer your shipping logistics through the preparation, planning, organization, and execution to reduce costs.

RM Mold

RM Mold