General Tolerance: +/-0.1mm

We are a Leading

Provider of top-quality CNC Laser Cutting Solutions:

We offer state-of-the-art CNC laser

cutting services that cater to all your needs. Our on demand

laser cutting service is nothing short of extraordinary,

and we take pride in our ability to deliver high-quality results within a quick

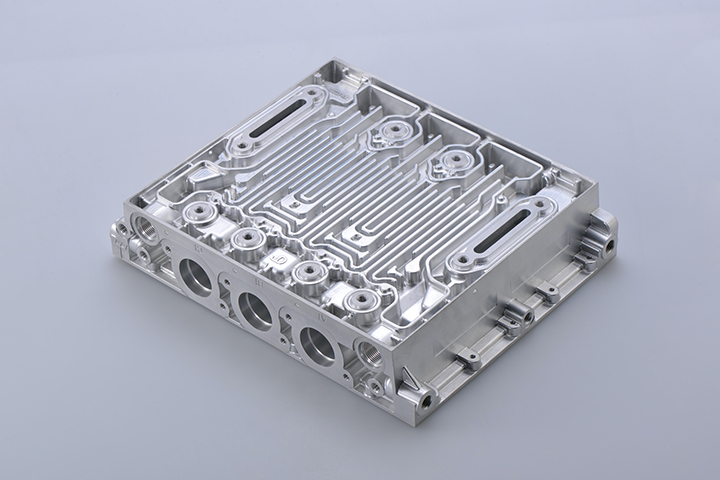

turnaround time. We use the latest technology in CNC metal

cutting services to ensure precision and accuracy every

step of the way. Whether you're looking for industrial-grade production or

custom-made design pieces, our team has got you covered with affordable rates

and unmatched customer service. With years of experience under our belt, we

have honed our skills to perfection and can guarantee that each piece produced

will be unique in its way. So why settle for less when you can choose us as a

trusted CNC metal cutting company for all your laser

Sheet Metal cutting needs?

Our CNC Metal

Cutting Company Follows Key Performance Indicators for Cutting Quality:

Quality control has a matchless part in CNC Sheet Metal cutting. Through sampling and process control, establishments can improve their performance. The same is valid for the metal-cutting process by CNC metal cutting companies. However, the question arises regarding how to measure the quality of metal cutting. When it comes to excellent and high-quality cutters, the likelihood of irregularities in the cutting process is reduced to a minimum. Nevertheless, attention should be paid to other critical key performance indicators (KPI) for cutting quality levels.

We follow key performance indicators (KPIs) to ensure cutting precision and excellence. Our team of experts meticulously monitors KPIs such as material wastage, cutting speed, accuracy, and surface finish. By adhering to these benchmarks, we guarantee superior cutting quality that exceeds industry standards. Whether it's stainless steel, aluminum, or any other metal, our state-of-the-art CNC machines deliver outstanding results. Experience the difference of working with a CNC metal cutting company that prioritizes KPIs and consistently delivers flawless metal cutting solutions. Your satisfaction is our ultimate goal.

Quality Control

Parameters Followed by Our CNC Metal Cutting Company:

Formation of the

Molten Metal – the control of this parameter is usually

done by manual inspection of the CNC Sheet Metal cutting. The information found

by checking refers to the focus of the laser beam or the laser cutter’s optic.

The Incision of the

Cut– a parameter that depends on the material being

used and is based on the tolerance, which is different for different metals.

The data obtained by inspecting the incision tells us about the size of the

laser beam infiltration into the metal.

The Puncture–The puncture of the metal is formed due to corrosive action, and it can significantly change the quality of the cut. This parameter is typically visually examined and qualitatively designated by our metal cutting company.

Cut Lines– the cutting lines during laser cutting are based on the speed at which a specific position metal is cut. This parameter is also visually inspected, and the information provided by the examination speaks about the need to fine-tune the cut parameters in terms of power and speed by CNC sheet cutting service.

Roughness –

a parameter that impacts the need for extra material handling after laser

cutting. The roughness is demarcated depending on the thickness of the metal

being cut.

Why Choose Laser

Cutting for Part Development?

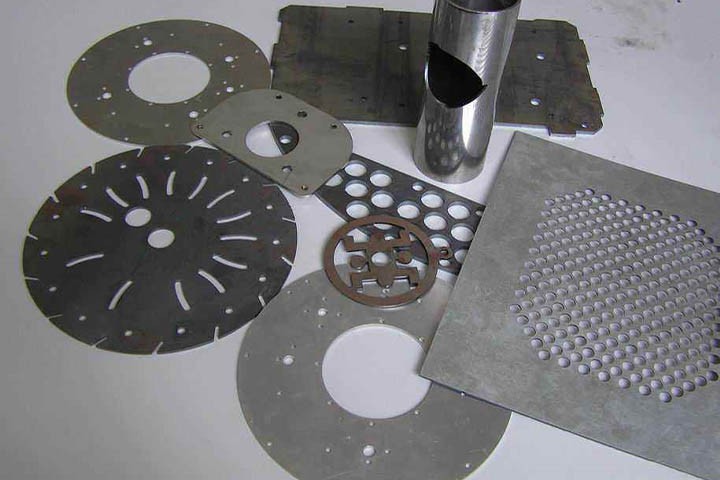

Metal cutting service is one of the most progressive

techniques, carrying accurate and quick results while generating the least

waste. It is feasible, especially for sensitive applications and cases dealing

with limited, affluent materials. Here are a few main reasons you should choose

laser cutting:

Accuracy and

Precision:

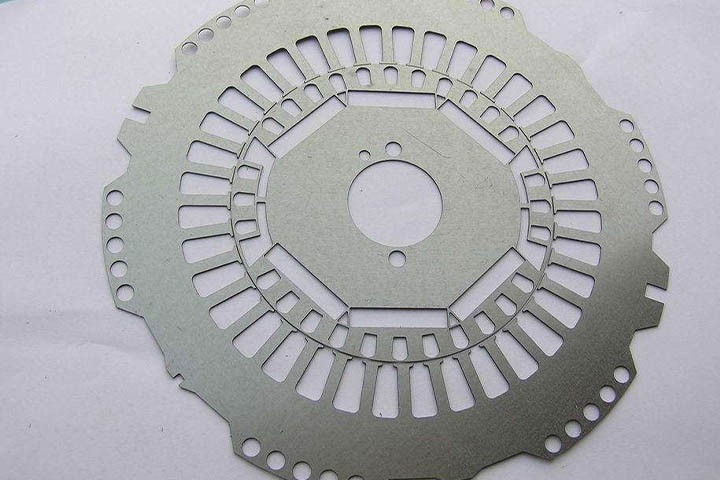

CNC laser cutting

service is matchless in accuracy. CNC programs the blades to

perform intricate cuts into shapes, and lasers produce these cuts with great

precision. A laser cutter makes clean edges and a smooth finish.

Quick Results:

Laser cutting is known for its volume to cut metal

accurately at quick paces. Laser cutters are suitable for low- and high-volume

production and can considerably reduce processing times.

Handle Complex Jobs

with Greater Consistency:

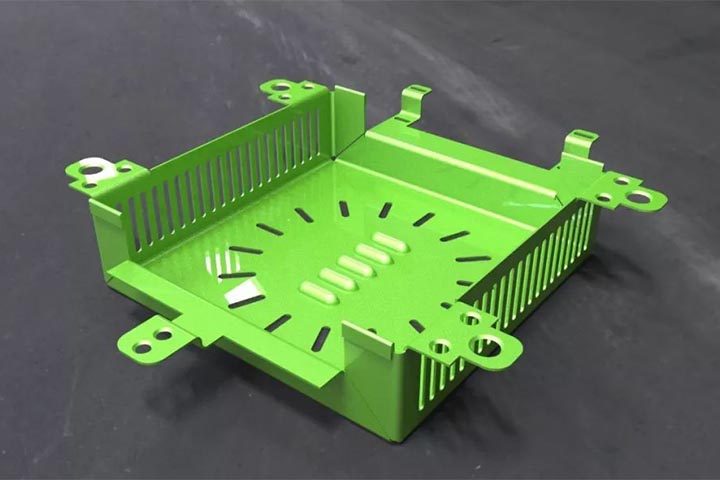

Our metal laser cutting service procedure can

handle more intricate and unusual geometries. The laser relies on CNC

technology, and the design elements have fewer limitations than other

techniques. Furthermore, a CNC laser can also churn out multiple parts at the

same time while dealing with Sheet Metals.

Low Waste:

The precision of the metal laser

cutting service indicates that you don’t have a lot of

waste material. It does an excellent job, mainly when you deal with expensive

and rare metals.

RM Mold

RM Mold