Can be shipped in 2~3days

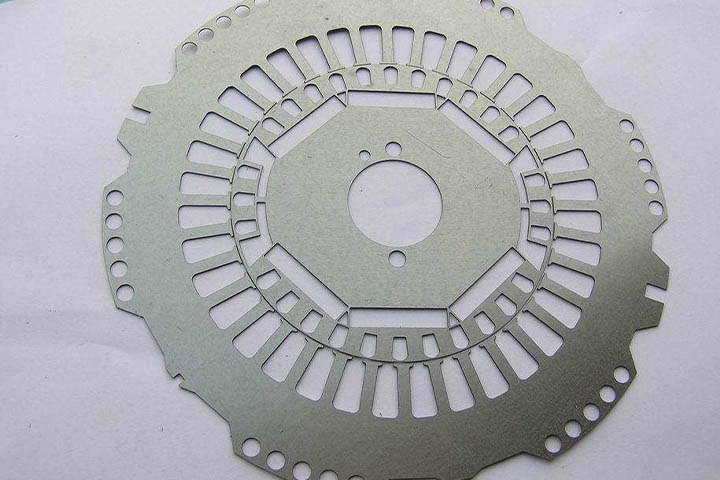

Print Size 800*800*450mm

Tolerance can be +/-0.1mm per 200mm

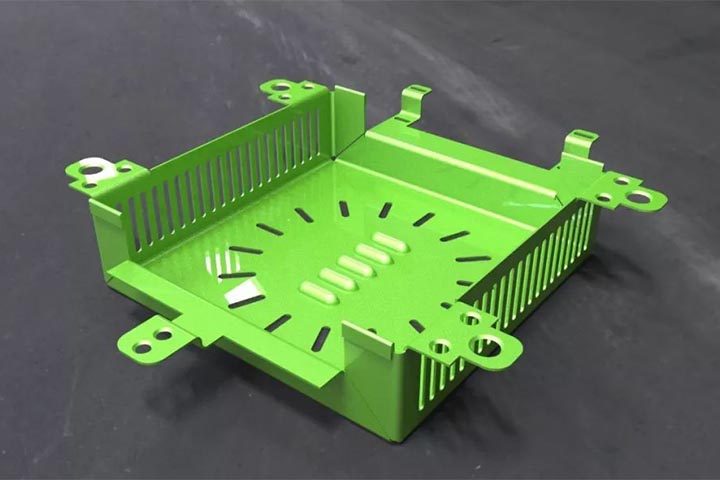

Can be painted/dyed/Vacuum Metalized/Silk Screen printed/Overmoulded.

SLA printing Materials used are Photosensitive in a Fluid Form:

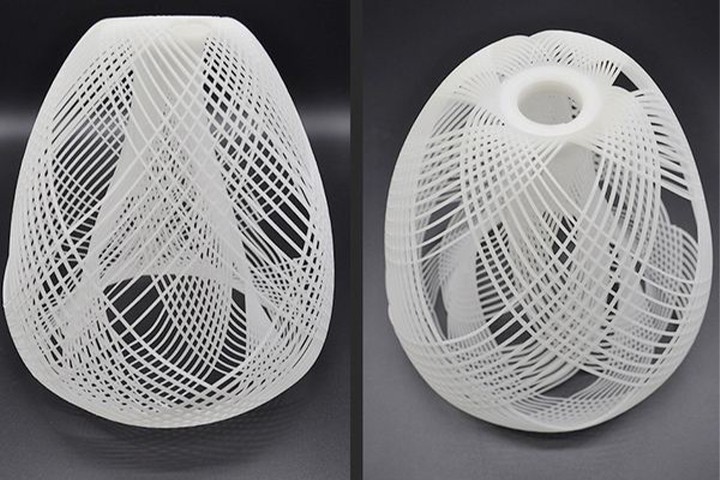

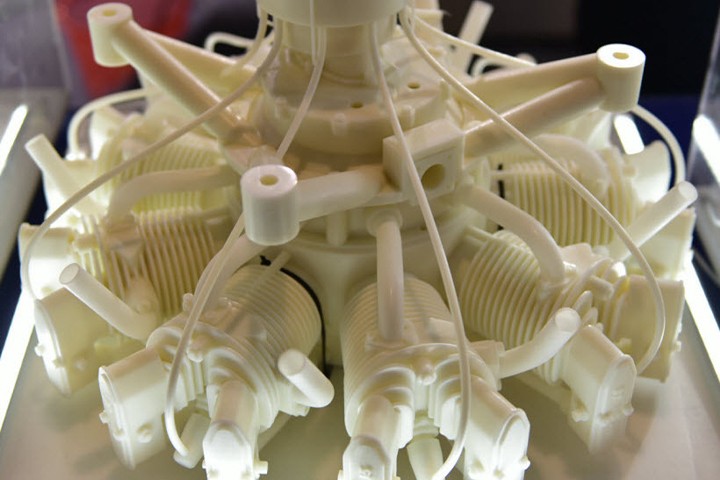

Stereo lithography (SLA printing) is an improved manufacturing process that fits in the vat photo polymerization family. Also identified as resin 3D printing, there are three leading 3D printing technologies related to vat polymerization: SLA, DLP, and LCD. The three technologies use a light source to treat a photopolymer resin. SLA is one of the most extensively used vats photo polymerization methods. In SLA printing services, SLA printing produces objects by selectively curing a polymer resin, layer by layer, using ultraviolet laser rays. The materials used in SLA are photosensitive that comes in a fluid form. SLA 3D printing works by first aligning the build platform in the tank of liquid photopolymer at a remoteness of one layer height for the surface of the liquid.

A UV laser generates the next layer by selectively curing and hardening the resin. During the SLA printing solidifying part of the photo polymerization process, the monomer carbon chains that compose the liquid resin are triggered by the light of the UV rays and convert solids, creating strong, indestructible ties between each other. The laser rays are fixated in an encoded path using a set of mirrors called galvos. The whole cross-sectional area of the model is glanced at, so the produced part is solidified. After the process, the part is in a partially-cured situation.

It necessitates further post-processing under UV light if extensive mechanical and thermal possessions are needed. Printing parts with SLS helps save money by dropping the need for molds, CNC bandwidth, or any other process of creating high-reliable parts. Parts can be printed fast on demand, which allows quick reiteration. Also, SLS parts are isotropic, meaning they have equivalent strength in every direction, which is not permanently the case with layered 3D-printed objects.

RM Mold

RM Mold