Can be shipped in 3days

Print Size: 600*390*390mm

No Need Support material

Material: PA12, PA12+GF

Tolerance: +/-0.15~0.2mm within 200mm

SLS Printing is an Atomic Response that Fuses Particles

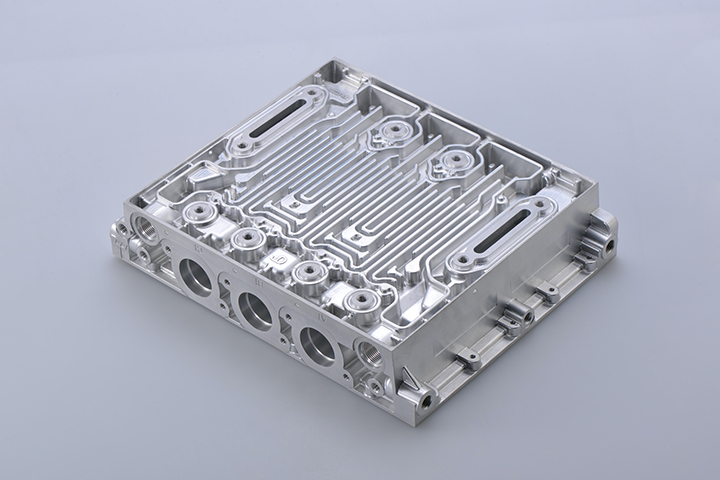

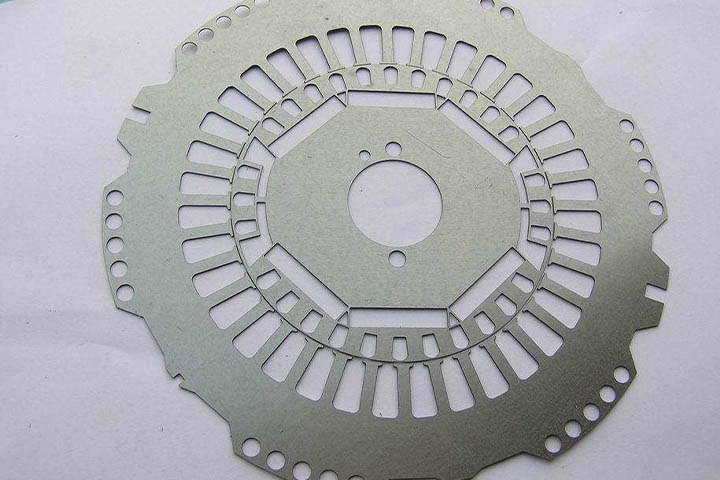

Selective laser sintering (SLS printing)

is a 3d printing process that uses extensive lasers to bind powdered material

into a solid structure. In this procedure, a printer lays down an even layer of

material and then strictly binds the layer, reiterating the deposition and binding

process until the component is complete. The object’s shape is produced by

directing a laser at the powder bed at detailed points in space, directed by a

digitally produced CAD (computer-aided design) file. Unlike discriminating

laser melting (SLM), which fully melts fine material together, binding causes

an atomic response that fuses particles, changing powdered material into a

solid structure.

SLS printing is characteristically only used to refer

to plastic, and ceramic 3D printers, 3D printers using a like process, are

referred to as DMLS or SLM machines. SLS machines can produce highly reliable

items, including precision, low-volume parts in the automotive and aerospace sector. SLS printing can produce geometrically intricate and highly accurate

parts from various materials. SLS 3D printing permits you to use multiple materials

and many finishings, achieving high-quality surfaces of components. Marketable

manufacturing is a real chance to adapt your creation to demand. You can evade

minimum order quantities, perfect for small or large-quantity production.

RM Mold

RM Mold